Introduction

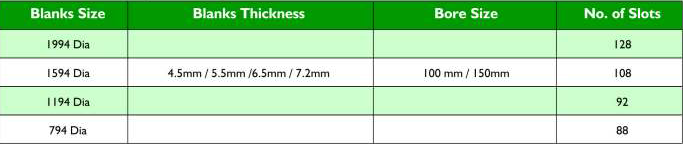

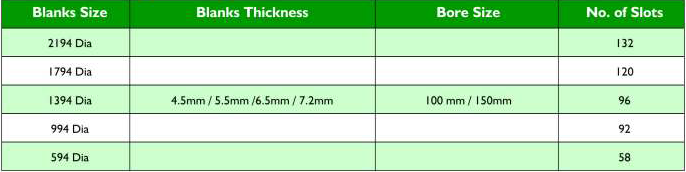

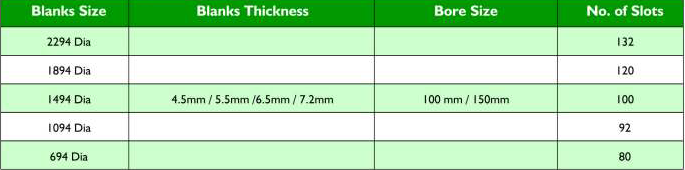

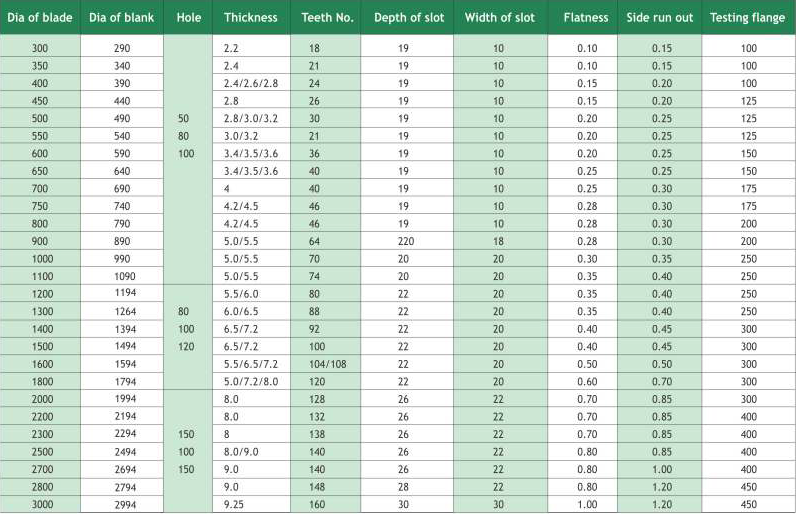

Pai and Pai Enterprices,the flagship company of the Pai and Pai group was established in 1971 as the distribution firm for leading manufactures of Metal finishing chemicals,electroplating plants and other allied equipments. The Pai and Pai group comprising of conglomerate of companies,is engaged in consulting,manufacture,distribution and support services of wide range of products to meet the specialized needs of various industries. Pai and Pai Enterprices plays pivotal role in granite industry by manufacturing and marking diamond saws and tools,circular saws,edge cutting saws and multi blades.Diamond segments supplied by us are mainly used for cutting cutting all kinds of granite blocks and slabs.The advantages are fast cutting,speed,smooth cutting and has long life....